Why wood?

We build our frames from wood because experience has taught us that it is the best material for the job, outperforming carbon fibre, titanium, steel and aluminium when used correctly.

-

A Natural Solution

For most of human existence wood has been our engineering material of choice, but in recent decades, with the coming of more ‘exotic’, man-made materials, the true value of wood has been largely forgotten.

Through the application of modern engineering design, digital manufacturing and traditional woodworking, we are on a mission to demonstrate the perfect application of nature’s wonder material.

Our experience and understanding of wood allows us to build strong and durable frames which possess the unique shock absorbing properties that only wood can confer.

-

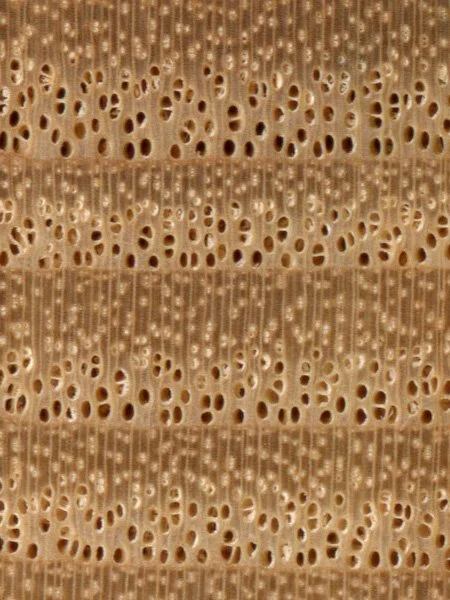

Microscopic Suspension

Wood is able to absorb shocks and vibration and thus deliver a super comfortable ride. This property is due to the cellular structure of wood, where the complex microscopic lignin matrix behaves like spring/damper combinations – the basis of every suspension system.

The natural vibration damping property, exhibited by all wood, has evolved to reduce the affects of wind induced resonance in the tree, and protects the branches and trunk from excessive deflections and the associated damage.

As with any bike, vibrations that come from the tyres rolling over an uneven surface are transmitted through the wheels and into the frame. What happens to these vibrations within the frame differs depending on the shape of the frame elements and the material from which the frame is made. Steel and aluminium transmit vibration very well, while carbon fibre can be ‘tuned’ to transmit slightly less.

The structure of wood means that the frame acts to absorb (in the spring) and dissipate (the damper) vibration, resulting in improved rider comfort and reduced fatigue.

materials on earth grew on trees …"

-

A Sustainable Material

We use British grown European Ash (Fraxinus Excelsior) because of its high flexibility, shock resistance, and resistance to splitting. It is sourced from sustainably managed British woodlands and milled a few miles away from our workshop, at Whitney Sawmills (above).

One of the joys of using wood is that this wonder material is naturally occurring and is all around us. Extraction and processing require minimal energy input and it can be replenished at the same rate that it can be used. In short, its use is sustainable.

Compare this with the carbon hungry mining, processing and transport involved in the production of more traditional materials and you can see why the use of wood has such significant environmental benefits. The nett amount of carbon emitted per tonne of planked timber is -457kg (in other words carbon is locked away) where as per tonne of steel it is 694kg, for aluminium it is 4,532kg and titanium is higher again!

Our frames are built from captured carbon in a process powered by sunlight.

-

An Engineering Material

At Twmpa Cycles one of our aims is to draw attention to the fact that wood, in combination with good design and a real understanding of the material, can be used in demanding engineering situations, providing benefits which many other highly processed materials cannot offer.

Morgan cars realised this many years ago and continue to use ash as the framework for their sports cars.

We continue to explore the possibilities for building wooden bike frames, developing new models and constantly reviewing and refining our understanding of this amazing material.